The oil and gas industry, known for its scale and complexity, increasingly relies on modular and efficient solutions to ensure safer, faster, and more flexible operations. One such solution that has transformed the landscape of upstream and downstream oil processes is the skid-mounted unit. These compact, pre-assembled systems play a pivotal role in the extraction, refining, and treatment of oil, offering enhanced mobility, operational efficiency, and integration.

At the forefront of this transformation is Chem-Unit, a company focused on the design, development, and manufacture of skid-mounted pilot units, medium-scale processing systems, production equipment, and laboratory automation. Chem-Unit's innovative approach enables oil and gas companies to optimize performance, reduce costs, and accelerate deployment timelines across various operational scales.

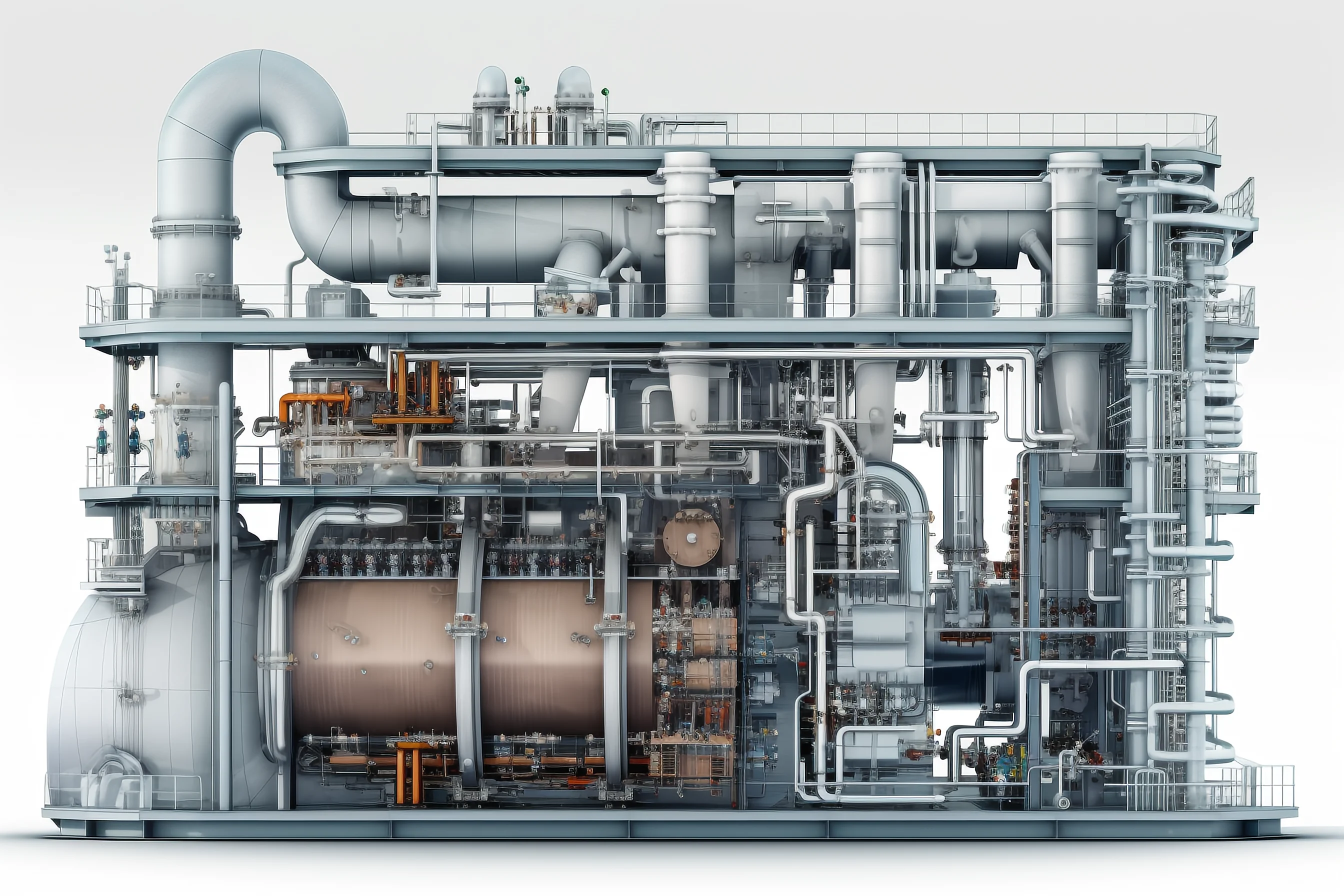

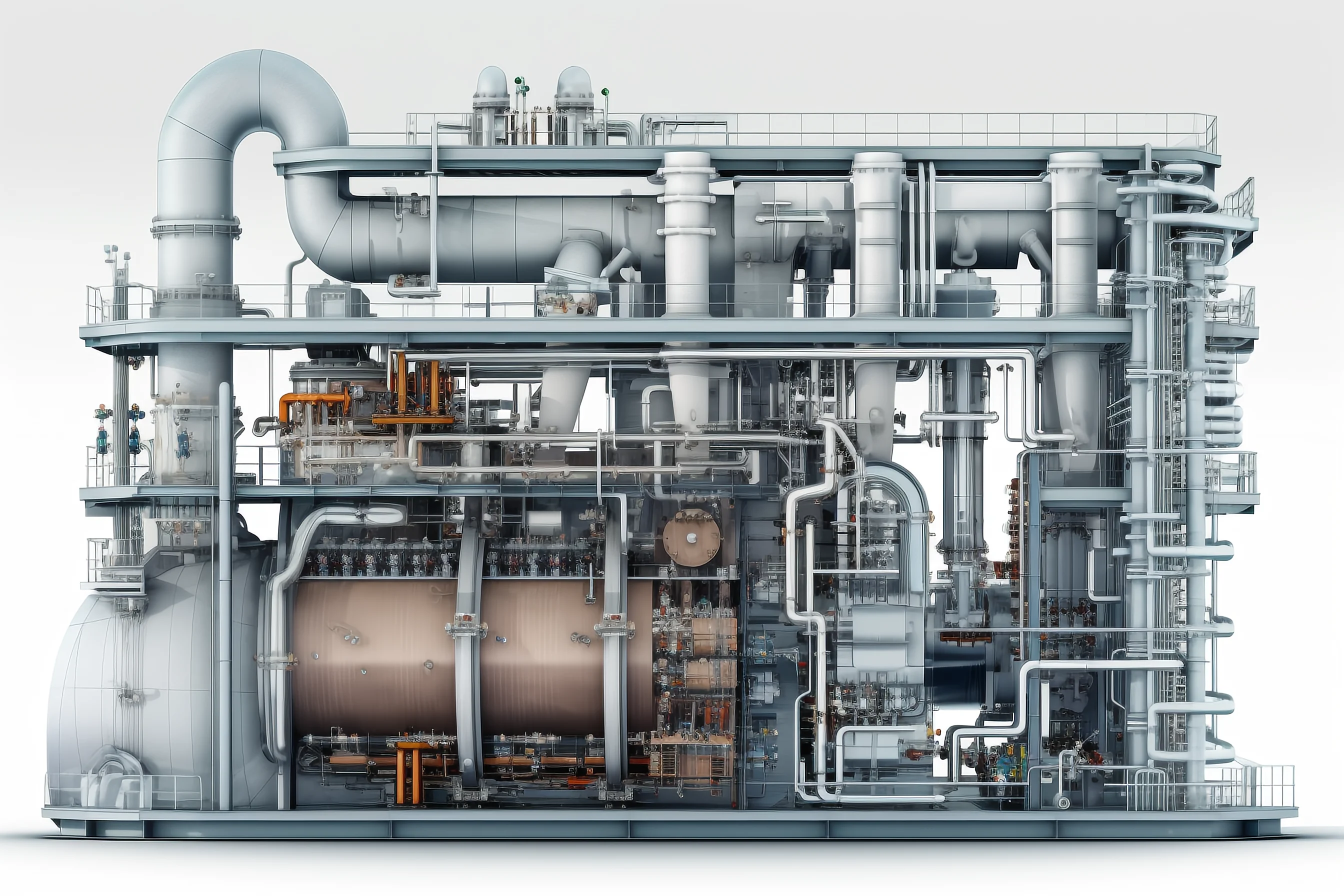

What Is a Skid-mounted Unit?

A skid-mounted unit is a self-contained system or module pre-assembled on a frame or “skid.” It integrates piping, instrumentation, control systems, and process equipment into a single transportable platform. These units are plug-and-play solutions—designed for rapid installation, commissioning, and relocation, making them ideal for remote or high-risk environments.

In oil industry applications, skid-mounted units are commonly deployed for:

Oil and gas extraction (wellhead processing)

Refining and upgrading operations

Treatment and separation of fluids and gases

Pilot-scale testing for new process validation

On-site production of specific petrochemical streams

Applications in Oil Extraction

During oil extraction, especially in onshore and offshore fields, skid-mounted systems provide a critical interface between the wellhead and downstream infrastructure. Their main functions include:

Three-phase separation (oil, gas, and water)

Crude stabilization

Dehydration and desalting

Gas compression and conditioning

These compact modules can be installed near the well site, reducing pipeline requirements and enabling early-stage production. For enhanced flexibility, Chem-Unit offers custom-engineered skid units designed to handle specific well conditions, fluid compositions, and production targets.

Applications in Oil Refining

In refineries, skid-mounted systems serve as modular blocks for:

Pilot plants and testing skids for refining process development

Catalytic reforming or hydrocracking pilots

Blending and fractionation units

Pre-treatment of feedstock streams

Chem-Unit’s skid-mounted pilot and medium-scale refining systems are ideal for technology verification, process intensification studies, or low-volume specialty product manufacturing. Each system is equipped with robust instrumentation, advanced control interfaces, and data acquisition capabilities—making them well-suited for both academic research and industrial application.

Applications in Oil Treatment and Environmental Management

Oil treatment processes often require advanced separation, purification, and emissions control technologies. Skid-mounted units are widely used in:

Produced water treatment

VOC and sulfur recovery systems

Flare gas recovery

Chemical injection and dosing

Slop oil recovery and recycling

With increasing environmental regulation, modular treatment systems enable operators to deploy targeted solutions without the footprint and complexity of permanent installations. Chem-Unit’s expertise in process design and integration ensures that each treatment skid complies with regulatory requirements and delivers consistent performance across varying flow conditions.

Advantages of Skid-mounted Units in the Oil Industry

1. Modular and Scalable

Systems can be designed for single well pads or multi-train refineries. As production scales, units can be added or modified without disrupting existing operations.

2. Reduced Installation Time

Pre-assembled and factory-tested, skid units dramatically cut down on field construction, enabling faster commissioning.

3. Enhanced Safety and Quality

Controlled manufacturing environments ensure compliance with international standards such as ASME, API, and IEC.

4. Portability and Reusability

Skids can be relocated, repurposed, or expanded to meet evolving production demands or field redeployments.

5. Cost-effectiveness

Lower capital expenditure due to reduced field labor, minimized downtime, and modular expansion options.

Chem-Unit: A Trusted Partner in Modular Process Systems

Chem-Unit has established itself as a technologically advanced and quality-driven enterprise in the field of skid-mounted systems and experimental process equipment. With deep experience in chemical process engineering, modular manufacturing, and automation, Chem-Unit offers:

Custom skid design and process simulation

Full mechanical, electrical, and control system integration

Pilot-scale to production-scale modular units

Automated experimental platforms and robotics

Whether for oil field service companies, refining R&D labs, or national energy corporations, Chem-Unit’s solutions are designed to accelerate innovation, reduce technical risk, and streamline process deployment.

Conclusion

As the energy industry evolves, the importance of modular, flexible, and intelligent processing systems is growing. Skid-mounted units have become indispensable tools in oil extraction, refining, and treatment—helping operators respond faster to market shifts, reduce costs, and meet strict safety and environmental standards.

By delivering high-performance, tailor-made skid solutions, Chem-Unit empowers oil and gas clients to explore new technologies, scale production efficiently, and operate with precision in even the most challenging environments. As the world transitions to smarter energy systems, Chem-Unit stands at the forefront—engineering innovation, one skid at a time.

Top Advantages of Skid-Mounted Unit Series for Modular Equipment Solutions

en.chem-unit.com

Shanghai Chem-Unit Technologies Co. Ltd.,