In the modern era of rapid data transmission and advanced communication technologies, high-frequency PCBs play a vital role in ensuring performance, reliability, and signal integrity. These boards are the backbone of high-speed communication systems, enabling faster signal flow and reduced losses across complex circuits. Understanding their design principles and manufacturing considerations is essential for achieving optimal results in next-generation communication equipment.

The Importance of High Frequency PCBs

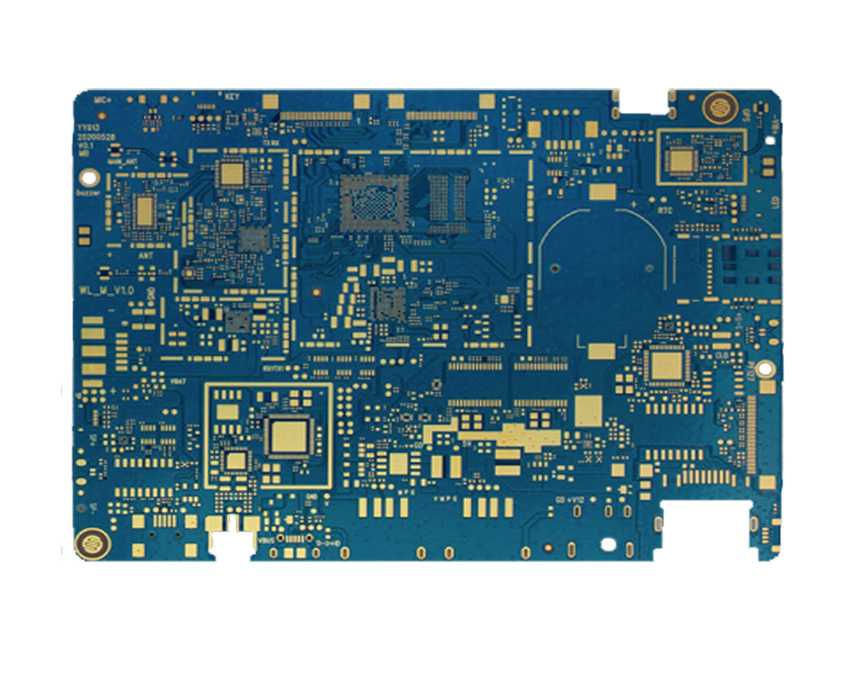

High-frequency printed circuit boards are engineered to handle signals above 1GHz, making them essential for applications such as 5G networks, radar systems, and satellite communications. These boards require materials with low dielectric loss, stable dielectric constants, and excellent thermal management to maintain signal integrity even under high-speed conditions.

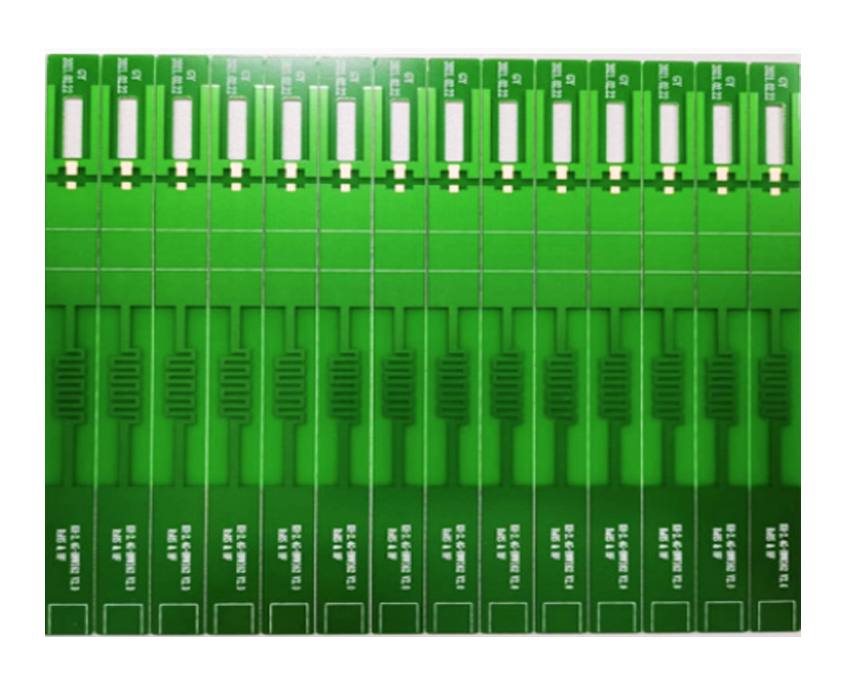

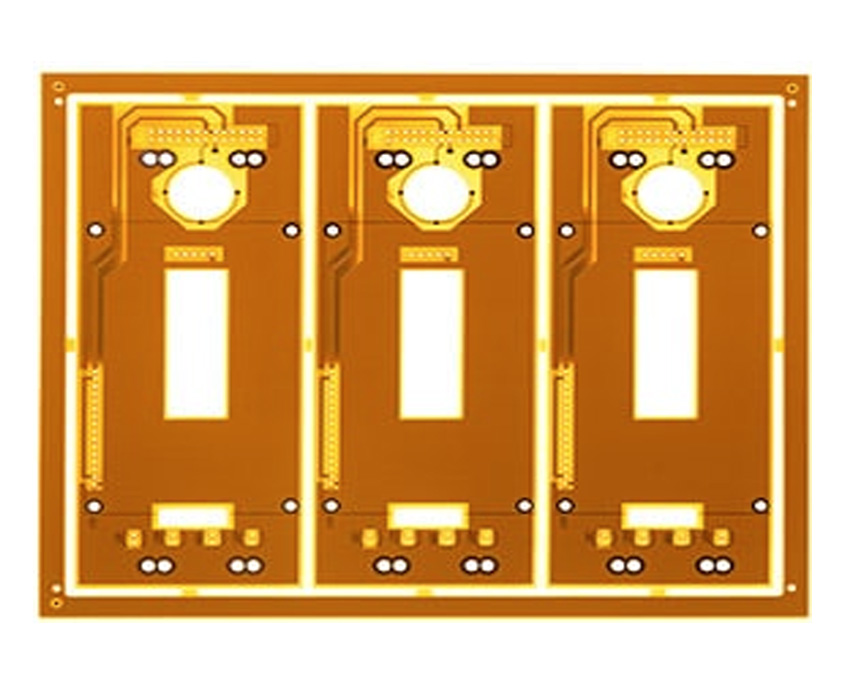

Shenzhen Zinpon Electronics Co., Ltd., a leading PCB and PCB assembly manufacturer based in China, specializes in producing high-quality high-frequency boards tailored to customer requirements. With advanced fabrication facilities and experienced engineering teams, Zinpon delivers PCBs designed to meet the challenges of high-speed signal transmission.

Material Selection and Design Considerations

The performance of a high-frequency PCB heavily depends on material choice. Common substrates such as FR4 are not suitable for extremely high-speed applications due to higher dielectric losses. Instead, materials like Rogers, Taconic, or PTFE (Teflon) laminates are preferred for their superior electrical properties.

Key design factors include:

-

Controlled impedance: Ensures consistent signal transmission and prevents reflection losses.

-

Layer stack-up optimization: Minimizes crosstalk and electromagnetic interference.

-

Copper surface quality: Smooth copper reduces signal attenuation at high frequencies.

By combining precise design and quality materials, manufacturers like Shenzhen Zinpon Electronics Co., Ltd. help customers achieve efficient and stable high-speed PCB solutions.

Challenges in Manufacturing and Assembly

Producing high-frequency PCBs requires precision manufacturing and strict quality control. Challenges include maintaining tight trace tolerances, managing thermal expansion, and ensuring reliable plating for vias. Zinpon’s advanced production techniques—such as laser drilling, automated optical inspection, and impedance testing—allow for consistent accuracy and dependable performance in every board produced.

PCB assembly for high-frequency systems also demands expertise. Proper soldering techniques, component placement, and inspection methods help prevent signal degradation and maintain long-term reliability.

Applications Across High-Speed Communication Fields

High-frequency PCBs are integral to many industries where fast and reliable data transfer is critical. Common applications include:

-

Base stations and 5G network infrastructure

-

Satellite communication systems

-

Automotive radar and navigation equipment

-

Wireless routers and IoT devices

By supporting these applications, Shenzhen Zinpon Electronics Co., Ltd. continues to provide the foundation for global high-speed connectivity and innovation.

Conclusion

As the demand for faster, more efficient communication grows, high-frequency PCBs have become a cornerstone of modern electronic design. Partnering with an experienced manufacturer like Shenzhen Zinpon Electronics Co., Ltd. ensures that every board meets stringent electrical, thermal, and mechanical requirements.

Through advanced technology, precise engineering, and a commitment to quality, Zinpon delivers PCB solutions that empower the future of high-speed communication systems—bridging the gap between innovation and reliability.

A Comprehensive Guide to Designing and Manufacturing High Frequency PCBs

www.zinponpcb.com

Shenzhen Zinpon Electronics Co, Ltd.