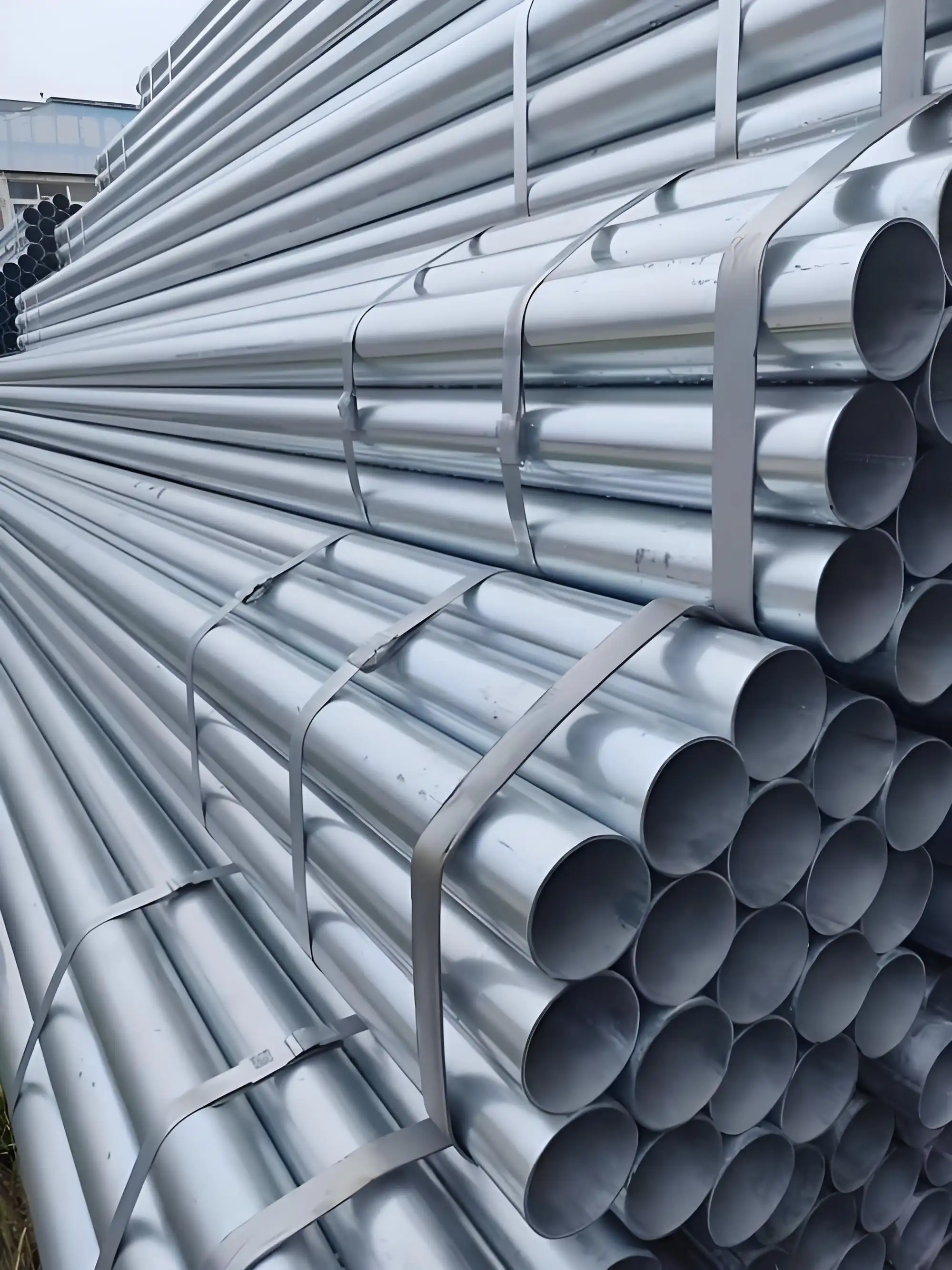

The reliability of engineering pipelines depends fundamentally on the strength, protection, and endurance of the materials chosen to construct them. Among the most widely used materials across industrial, municipal, and construction sectors are galvanized steel pipes. Known for their ability to withstand corrosion and retain mechanical strength under demanding conditions, they serve as essential conduits in systems that carry water, gas, oil, and other critical fluids.

This article explores in depth the significance of galvanized steel in engineering pipelines, emphasizing the scientific principles behind galvanization, its performance characteristics, and the standards of quality upheld by Guangqi, a company dedicated to producing and supplying a comprehensive range of high-quality steel pipe products.

The Enduring Role of Galvanized Steel in Engineering Pipelines

In engineering, pipelines represent more than simple transportation channels. They are the arteries of infrastructure, ensuring the steady and safe movement of essential resources. Within this system, engineering pipelines galvanized steel pipes have emerged as a cornerstone solution due to their balance between cost efficiency, strength, and resistance to environmental degradation.

Steel is inherently strong, but when exposed to moisture, oxygen, or chemicals, it tends to rust and lose integrity over time. Galvanization provides an effective solution by coating steel with a layer of zinc, which shields it from corrosive agents and ensures that the base metal remains structurally sound. This layer of protection is both passive and active—it prevents corrosion through isolation and also sacrifices itself electrochemically to preserve the underlying steel.

Companies like Guangqi have recognized the universal demand for such durability and have devoted themselves to advancing galvanizing technologies to support modern infrastructure needs.

The Science Behind Galvanization and Corrosion Protection

The galvanization process is a well-established metallurgical practice that enhances the longevity of steel by applying a protective zinc coating. This can be achieved through several methods, such as hot-dip galvanizing, pre-galvanizing, or electro-galvanizing. In each process, the purpose remains constant: to establish a barrier and a cathodic protective layer that prevents steel from oxidizing.

When steel is galvanized, the zinc coating performs two critical protective actions:

Barrier Protection – The zinc layer isolates steel from direct contact with water, air, and corrosive chemicals.

Cathodic Protection – Zinc, being more reactive than steel, corrodes first, thereby preventing the steel beneath from rusting.

In hot-dip galvanizing, the steel pipe is immersed in molten zinc at carefully controlled temperatures. The process forms intermetallic layers of zinc and iron that bond metallurgically with the steel substrate, creating a coating that is both tough and adhesive. This metallurgical bond ensures that even if the outer zinc layer is abraded, the underlying alloy layers continue to protect the steel.

For engineering pipelines galvanized steel pipes, this process ensures that pipelines remain durable in harsh conditions, from humid coastal regions to industrial zones where exposure to chemicals or pollutants is unavoidable.

The Relationship Between Corrosion Resistance and Service Durability

Corrosion is an inevitable challenge in metal infrastructure, but its rate can be significantly slowed with proper material design. Galvanized steel pipes are uniquely suited to environments where long-term durability is essential. The zinc coating corrodes gradually, forming protective zinc carbonate films that slow further reaction with oxygen and moisture.

In water distribution systems, fire protection networks, industrial installations, and agricultural irrigation, galvanized steel pipelines demonstrate an ability to remain structurally sound over decades of service. This endurance not only extends the pipeline’s operational life but also reduces maintenance frequency, which translates directly into economic benefit.

For enterprises such as Guangqi, understanding this balance between corrosion resistance and material longevity guides every stage of production—from raw material selection to coating application and final inspection.

Manufacturing Excellence and Quality Control at Guangqi

The performance of engineering pipelines galvanized steel pipes depends heavily on manufacturing quality. At Guangqi, this principle forms the foundation of production operations. Guangqi integrates advanced manufacturing techniques and strict inspection systems to ensure each pipe meets international quality standards.

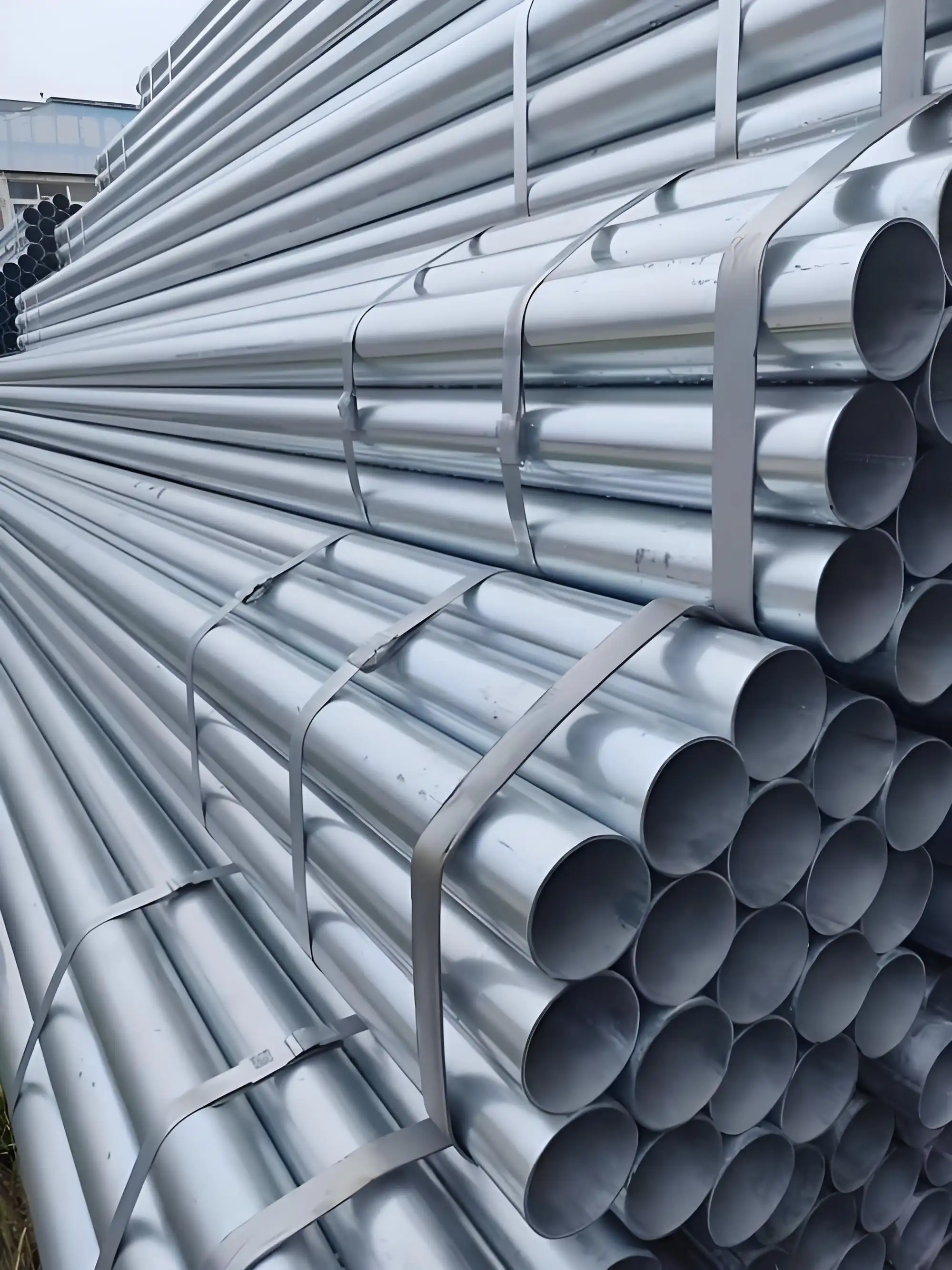

The production process begins with the careful selection of raw steel that meets specified chemical and mechanical criteria. Each batch is cleaned, pickled, and prepared meticulously before galvanization to guarantee optimal adhesion between the steel surface and zinc layer. During the galvanizing stage, temperature, immersion time, and withdrawal speed are precisely controlled to achieve a uniform and durable coating.

Post-galvanization, every pipe undergoes comprehensive inspection procedures such as:

Coating thickness measurement

Visual examination for surface uniformity

Adhesion and bend testing

Accelerated salt spray corrosion testing

Dimensional verification

These measures ensure that the final product delivers both mechanical integrity and corrosion resistance suitable for critical engineering applications. Guangqi’s dedication to detail in these procedures positions it as a dependable supplier of galvanized steel products for domestic and international markets.

The Structural Integrity of Galvanized Steel Pipes in Pipeline Systems

While the zinc coating provides corrosion protection, the underlying steel delivers the strength that pipeline systems rely on. Galvanized steel possesses an excellent balance between tensile strength and ductility, allowing it to endure high internal pressures and external mechanical forces without deformation.

In engineering pipelines, where variations in pressure, vibration, and temperature can stress materials, galvanized steel pipes provide a stable structural foundation. They maintain their shape under load, resist fatigue from repeated stress cycles, and perform reliably under thermal expansion and contraction.

For buried or exposed installations, the combination of a robust steel substrate and a zinc-based protective coating ensures the pipeline’s capacity to handle both environmental and mechanical challenges. This dual nature of strength and protection is precisely why galvanized steel remains a preferred material among engineers and contractors.

Environmental Conditions and Corrosion Performance

The performance of galvanized steel is highly influenced by its surrounding environment. Different atmospheric and soil conditions affect how fast zinc corrodes and how long the coating can protect the steel.

In urban and industrial environments, airborne pollutants and acidic compounds can accelerate zinc corrosion, while rural environments are relatively benign. Coastal regions, with high humidity and salt concentration, present the harshest challenges, requiring thicker or double coatings for extended protection.

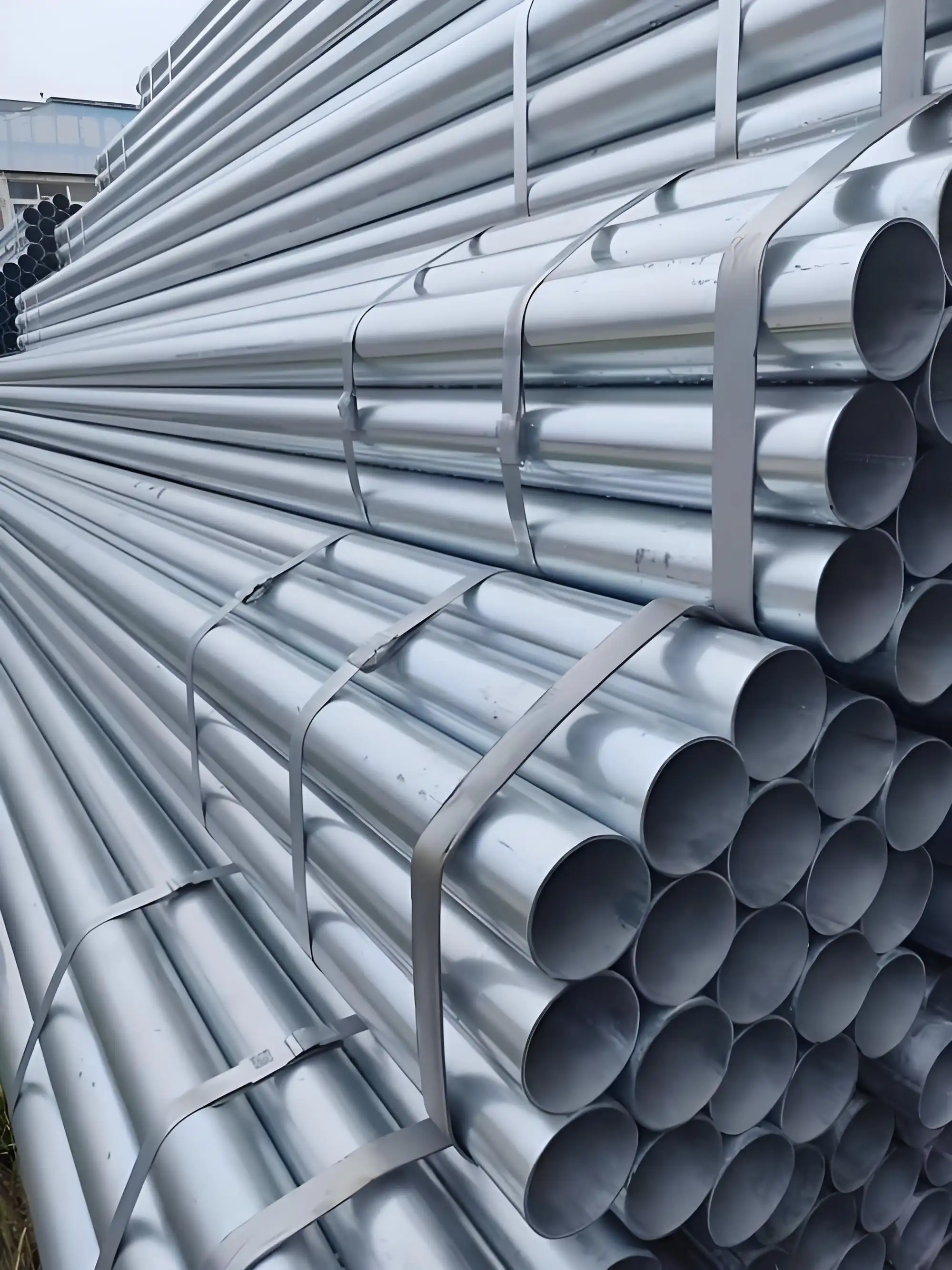

To address these diverse conditions, Guangqi manufactures a range of product types including galvanized steel pipes, galvanized steel-plastic composite pipes, coated pipes, galvanized square and rectangular tubes, and ductile iron pipes. Each product type offers different levels of protection, strength, and application suitability.

For instance, steel-plastic composite pipes combine the toughness of steel with the corrosion immunity of plastic, making them suitable for aggressive chemical or marine environments. Similarly, coated pipes provide an additional outer or inner barrier for enhanced corrosion control.

Through material versatility and coating precision, Guangqi ensures that each product can adapt to a specific environmental challenge in modern engineering.

The Economic and Operational Advantages of Galvanized Steel Pipelines

The decision to use engineering pipelines galvanized steel pipes is often driven by cost-effectiveness over the entire lifecycle of a project. Although the initial investment in galvanized steel may be slightly higher than in untreated materials, the overall savings achieved through lower maintenance and extended service life make it a more economical choice.

Key economic benefits include:

Reduced need for frequent maintenance or replacement

Lower downtime in industrial systems

Simplified installation processes

Compatibility with a wide range of fittings and standards

Additionally, galvanized steel’s mechanical robustness ensures that it can withstand transportation and handling stresses during installation, minimizing the likelihood of damage before service.

By optimizing coating quality and ensuring consistent manufacturing, Guangqi helps its clients reduce total project costs while maintaining safety and compliance in pipeline systems.

Applications of Galvanized Steel in Engineering and Infrastructure

The versatility of engineering pipelines galvanized steel pipes allows them to serve in multiple sectors:

Water Supply and Distribution Systems

Galvanized steel is a traditional yet effective choice for municipal water delivery. Its ability to resist rusting ensures water purity and long service intervals, making it ideal for both above-ground and buried networks.

Fire Protection Systems

In fire sprinkler systems, reliability is paramount. The strength and corrosion resistance of galvanized steel ensure that water pressure remains consistent when needed most.

Industrial Process Pipelines

Factories and refineries use galvanized steel pipes to transport cooling water, compressed air, and other utility services. The coating protects against moisture and chemical attack common in industrial environments.

Agricultural and Irrigation Networks

Rural infrastructure often relies on galvanized steel for irrigation due to its balance of cost and endurance under varying climatic conditions.

Construction and Structural Applications

Beyond fluid transport, galvanized steel pipes and tubes are widely used as scaffolding, supports, and protective conduits in buildings, bridges, and machinery frameworks.

In each of these applications, Guangqi provides tailored product solutions, ensuring that the chosen pipe type aligns with specific performance and safety requirements.

Composite and Coated Pipe Technologies at Guangqi

While traditional galvanized steel remains a proven standard, advancements in composite and coated pipe technologies offer enhanced resistance for specialized uses. Guangqi integrates these developments into its product range to serve broader engineering demands.

Galvanized Steel-Plastic Composite Pipes

These pipes combine the mechanical strength of steel with the chemical inertness of plastic. The inner plastic lining prevents fluid-induced corrosion, while the outer galvanized layer shields against environmental attack. This configuration is particularly advantageous for chemical plants, marine pipelines, and municipal systems requiring hygienic water flow.

Coated Steel Pipes

By applying additional epoxy or polyethylene coatings on top of the zinc layer, the corrosion resistance of galvanized pipes is significantly improved. This dual-protection approach is ideal for buried pipelines and systems exposed to corrosive soils or atmospheres.

Ductile Iron Pipes

Guangqi’s range also includes ductile iron pipes, known for their high pressure tolerance and impact resistance. These are often used in large-scale water mains, sewage systems, and industrial distribution networks where mechanical load-bearing capability is critical.

Each technology offered by Guangqi demonstrates the company’s commitment to combining corrosion resistance, durability, and structural reliability under one engineering philosophy.

Engineering Standards and Compliance

The effectiveness of engineering pipelines galvanized steel pipes relies on strict adherence to national and international standards. Guangqi ensures that its products conform to widely recognized specifications such as ASTM, ISO, BS, and GB standards, depending on client requirements.

Conformance to these standards guarantees that each pipe meets the specified parameters for wall thickness, coating weight, tensile strength, weld integrity, and dimensional precision. Continuous improvement, laboratory testing, and third-party certification maintain the credibility

www.gqsteelpipe.com

Foshan Nanhai Guangqi Steel Industry Co., Ltd.