Formwork is a fundamental component in modern construction, providing the molds necessary to shape concrete structures with precision, stability, and efficiency. Proper formwork design and implementation are crucial for achieving high-quality construction results, reducing labor costs, and ensuring safety on site. From residential buildings to large-scale commercial projects, understanding the types, materials, and best practices of formwork is essential for construction professionals.

Types of Formwork in Modern Construction

Formwork systems can be categorized based on material and construction methods. The most commonly used types include:

-

Timber Formwork

Timber formwork is traditional and versatile, often used for small-scale projects or irregular shapes. It is easy to cut and assemble but requires frequent replacement due to wear and lower durability compared to modern systems. -

Steel Formwork

Steel formwork provides excellent strength and durability, making it suitable for large-scale or repetitive projects. It can be reused multiple times and maintains precise dimensions, ensuring uniformity across structures. -

Aluminum Formwork

Lightweight yet strong, aluminum formwork allows faster assembly and reduces labor effort. It is ideal for high-rise buildings and projects requiring rapid construction cycles. -

Plastic and Composite Formwork

These systems are increasingly popular for lightweight, modular applications. They offer easy cleaning, flexibility for curved or complex shapes, and resistance to moisture and corrosion. -

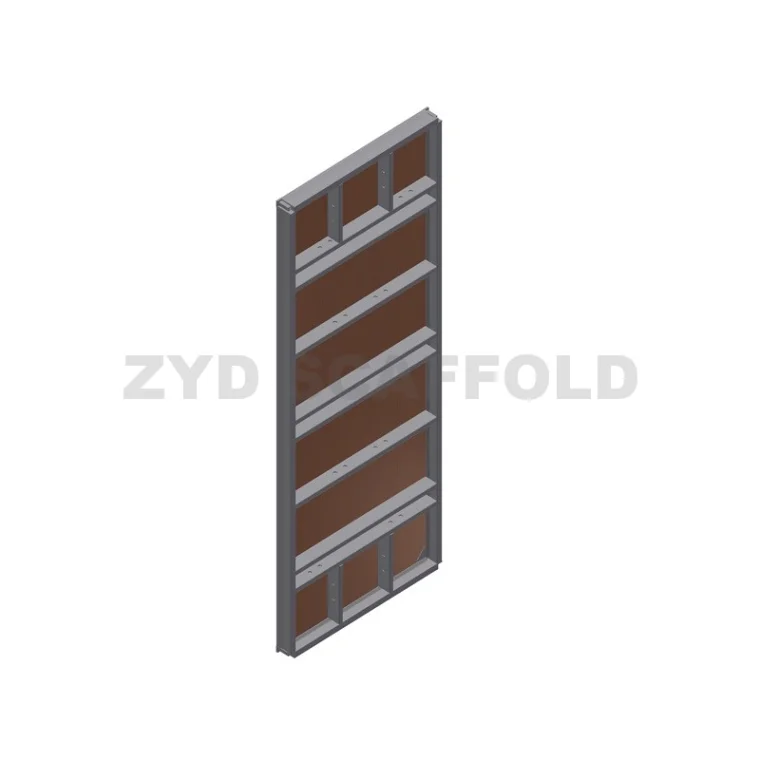

Modular and System Formwork

System formwork integrates standardized panels and supporting structures, enabling quick assembly and disassembly. It is widely used in modern construction due to its efficiency and consistency.

Materials Used in Formwork

The choice of material impacts both performance and cost-effectiveness. Common formwork materials include:

-

Timber – affordable and adaptable for irregular shapes but less durable.

-

Steel – strong, reusable, and suitable for large-scale or high-precision projects.

-

Aluminum – lightweight, durable, and reduces labor effort.

-

Plastic/Composite – modular, moisture-resistant, and suitable for curved designs.

High-quality formwork materials ensure stability during concrete pouring, prevent leakage, and help achieve smooth, defect-free concrete surfaces.

Best Practices for Efficient Formwork Use

To maximize the efficiency and safety of formwork systems, construction teams should follow several best practices:

-

Proper Planning and Design

Before construction begins, detailed formwork planning ensures correct panel sizing, load distribution, and alignment. Advanced modeling software can simulate stresses and optimize layout. -

Quality Materials and Components

Using durable materials and precision-manufactured components reduces the risk of deformation or failure. Partnering with trusted suppliers ensures reliable, high-quality formwork products. -

Regular Maintenance and Inspection

Formwork systems should be inspected for cracks, corrosion, or wear before each use. Proper maintenance extends service life and improves safety. -

Safe Assembly and Handling

Correct assembly procedures, secure connections, and safe handling techniques prevent accidents and ensure consistent concrete shapes. -

Reuse and Sustainability

Whenever possible, reuse formwork panels and components to reduce material waste and project costs, supporting sustainable construction practices.

How ZYD Enhances Modern Formwork Solutions

ZYD is a trusted supplier of scaffolding and formwork solutions, offering scaffolding systems, supports, molds, and barriers to meet diverse construction needs. Their innovative products are manufactured using advanced technologies and high-quality materials, ensuring safety, durability, and efficiency on the job site.

By integrating ZYD formwork and support systems, construction projects can achieve faster assembly, reduced labor requirements, and high-quality concrete finishes, all while maintaining industry-standard safety protocols.

Conclusion

Formwork is an essential element of modern construction, with a wide variety of types and materials available to suit different project requirements. Following best practices for design, assembly, and maintenance ensures optimal performance, safety, and cost efficiency.

Partnering with reliable suppliers such as ZYD SCAFFOLD provides access to innovative, high-quality formwork and support solutions, helping construction teams meet modern demands with precision and confidence.

www.zydscaffold.com

Zhong Yue Da Hardware & Plastic Co., Ltd.