Precision manufacturing has become a cornerstone of modern industrial development. As industries such as aerospace, automotive, medical devices, and electronics pursue ever more complex designs, the demand for machining methods capable of achieving tighter tolerances, smoother finishes, and faster production cycles continues to grow. At the heart of this evolution is five-axis cradle machining technology, a method that allows manufacturers to produce complex components with unmatched accuracy and efficiency.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd., a well-established enterprise specializing in CNC machining centers, wire-cutting machines, electrical discharge machines (EDM), and milling equipment, has been a driving force in promoting advanced machining solutions. By integrating five-axis cradle machining into its product lineup and services, the company demonstrates how precision technology can elevate the capabilities of manufacturers worldwide.

Understanding the Essence of Five-Axis Cradle Machining

Five-axis machining refers to the ability of a machine tool to move a workpiece or cutting tool along five different axes simultaneously. In contrast to conventional three-axis machining, which operates along the X, Y, and Z axes, five-axis machining introduces rotational movements that significantly expand the machining envelope.

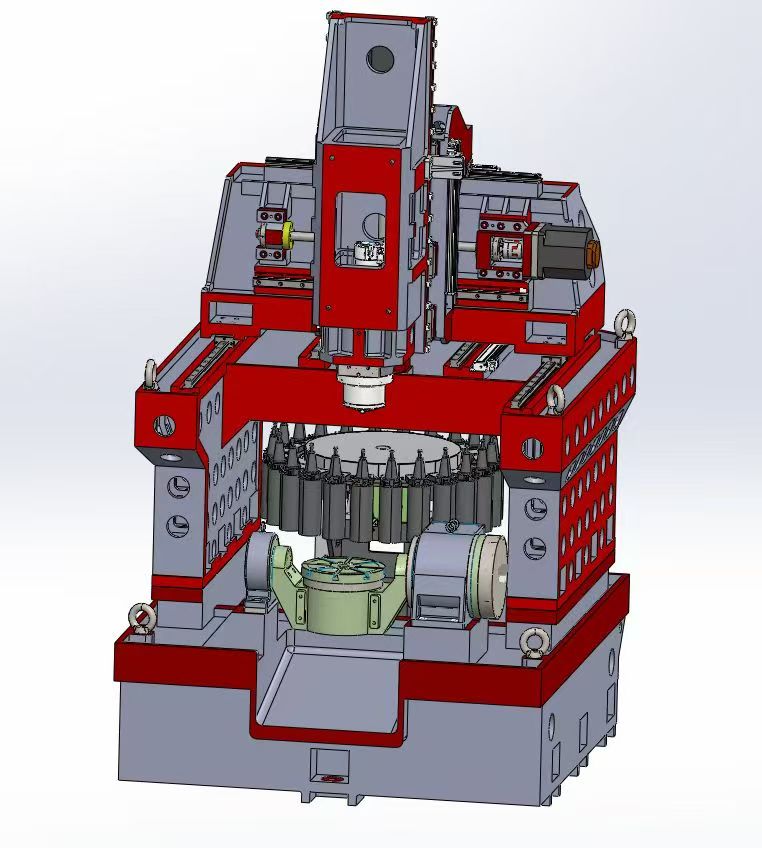

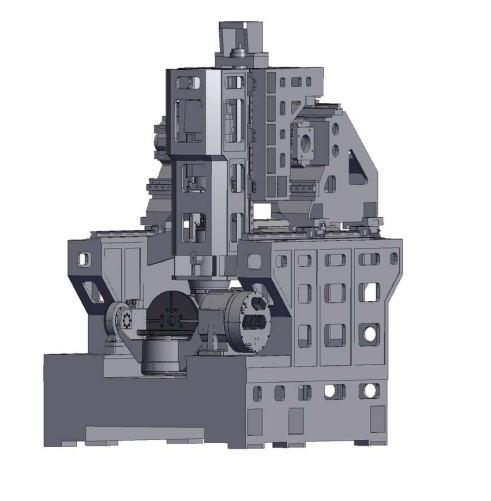

The “cradle” design is a specific configuration in which the workpiece is mounted on a tilting cradle, enabling rotational movements that enhance accessibility. This design allows cutting tools to reach areas that would otherwise require multiple setups or even be impossible to machine.

Key benefits include:

Complex Geometry Production: Intricate parts such as turbine blades, impellers, and medical implants can be produced with fewer limitations.

Reduced Setups: Multi-sided machining can be achieved in a single setup, improving efficiency.

Improved Surface Finish: The tool maintains optimal cutting angles, reducing tool marks and improving surface quality.

Greater Accuracy: Alignment errors are minimized since repositioning is less necessary.

For manufacturers seeking to meet the rigorous standards of high-precision industries, these benefits translate directly into competitiveness and long-term growth.

The Role of Five-Axis Machining in Industrial Sectors

Industries across the globe have embraced five-axis cradle machining for its versatility and performance advantages. Each sector leverages its capabilities in unique ways:

Aerospace: Jet engines, turbine blades, and structural components demand high strength-to-weight ratios and complex shapes. Five-axis machining ensures both precision and efficiency.

Automotive: From prototype development to high-performance engine parts, the technology supports innovation in lightweight and aerodynamic designs.

Medical Equipment: Surgical tools, orthopedic implants, and dental components require both biocompatibility and extreme accuracy, making five-axis machining indispensable.

Energy Industry: The production of impellers, rotors, and turbine components benefits greatly from reduced machining time and enhanced structural integrity.

Electronics and Communication: With miniaturization trends, five-axis machining offers a pathway to creating smaller, more complex housings and components with exact specifications.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.: A Trusted Innovator

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. has established itself as a leading enterprise in China’s precision machinery sector. With years of dedication to research, production, and sales, the company has built a reputation for reliability, technical expertise, and customer-centric solutions.

The company’s product portfolio includes:

CNC Machining Centers: Known for high stability, accuracy, and versatility, these machines cater to diverse industries requiring precision cutting and shaping.

Wire-Cutting Machines: Ideal for processing hardened steels and intricate profiles, ensuring clean cuts with minimal waste.

Electrical Discharge Machines (EDM): Offering unmatched accuracy in machining conductive materials, perfect for molds and dies.

Milling Equipment: Robust and adaptable, suited for a range of tasks from rough cutting to fine finishing.

By incorporating five-axis cradle machining technology into its offerings, Suzhou Zhiquan bridges the gap between innovation and accessibility. Customers benefit not only from cutting-edge machinery but also from comprehensive after-sales support and consultation.

Operational Advantages of Cradle Design

Among the many configurations of five-axis machining, the cradle design stands out for its simplicity, rigidity, and ergonomic use. Manufacturers gain several advantages when choosing this setup:

Stable Clamping: The cradle ensures the workpiece remains firmly secured, reducing vibration and ensuring better tool engagement.

Wide Accessibility: Tilting and rotating movements allow seamless access to undercuts, deep pockets, and curved geometries.

Consistent Quality: By eliminating multiple setups, part quality remains consistent across batches.

Tool Longevity: Improved tool orientation reduces wear, extending tool life and lowering operating costs.

Suzhou Zhiquan’s machines emphasize these principles, ensuring customers experience both performance reliability and cost-efficiency.

Integration with Digital Manufacturing

Modern five-axis machines do not operate in isolation. They form part of a digital manufacturing ecosystem where computer-aided design (CAD), computer-aided manufacturing (CAM), and advanced simulation tools play critical roles. The synergy between hardware and software allows:

Accurate Programming: CAM software calculates optimal toolpaths that fully exploit five-axis capabilities.

Simulation and Verification: Virtual machining prevents collisions, minimizes errors, and ensures smooth operations.

Data-Driven Efficiency: Real-time monitoring systems improve productivity and predictive maintenance.

Customization: Prototypes and small-batch production can be efficiently managed, reducing lead times.

Suzhou Zhiquan aligns with these digital trends, ensuring its machines are compatible with leading CAD/CAM platforms, enabling clients to integrate seamlessly into Industry 4.0 practices.

Commitment to Quality and Customer Success

Beyond machinery, what sets Suzhou Zhiquan apart is its commitment to building partnerships. The company emphasizes:

Rigorous Quality Control: Every machine undergoes strict testing before delivery, ensuring consistency.

Tailored Solutions: Machines can be customized to meet specific production needs.

Technical Training: Customers receive comprehensive training to maximize operational efficiency.

Global Reach: With a growing presence beyond China, the company provides solutions to an international customer base.

This dedication positions Suzhou Zhiquan as not merely a supplier but as a long-term ally in the pursuit of manufacturing excellence.

Sustainability and Resource Efficiency

As sustainability becomes central to global manufacturing, five-axis cradle machining contributes significantly by:

Reducing Waste: Precision cutting minimizes material scrap.

Energy Efficiency: Shorter machining times mean less energy consumption.

Longer Tool Life: Reduced tool wear translates into fewer replacements and lower resource consumption.

Optimized Production: Batch consistency reduces rework, saving time and resources.

Suzhou Zhiquan actively promotes green manufacturing principles, aligning its solutions with both economic and environmental goals.

Conclusion

Five-axis cradle machining technology has transformed the landscape of precision manufacturing. Its ability to handle complex geometries, improve efficiency, and enhance product quality has made it indispensable across industries. Suzhou Zhiquan Electromechanical Equipment Co., Ltd., with its extensive expertise in CNC machining centers, EDM, wire-cutting, and milling machines, embodies the progress and promise of this technology.

By providing advanced equipment, personalized solutions, and strong customer support, the company not only advances manufacturing standards but also empowers clients to compete on a global scale. Precision, efficiency, and innovation converge in five-axis cradle machining, and with trusted partners like Suzhou Zhiquan, the journey of excellence continues.

How High-Speed Five-Axis Cradle Machining Centers Revolutionize Precision Manufacturing

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.