Precision ring gears are critical mechanical components widely used across various sectors of engineering machinery due to their ability to transmit high torque, ensure precise motion control, and maintain performance integrity under demanding operational conditions. These gears, often customized with tight tolerances and manufactured using advanced processes like hobbing, shaping, or grinding, are integral to systems that demand high reliability, reduced backlash, and smooth rotation. In this blog post, as a high performance industrial gear manufacturing factory, Longruifa will share the applications of precision ring gear in engineering machinery.

Precision Ring Gear in Engineering Machinery Applications

1. Fundamentals of Precision Ring Gear Design

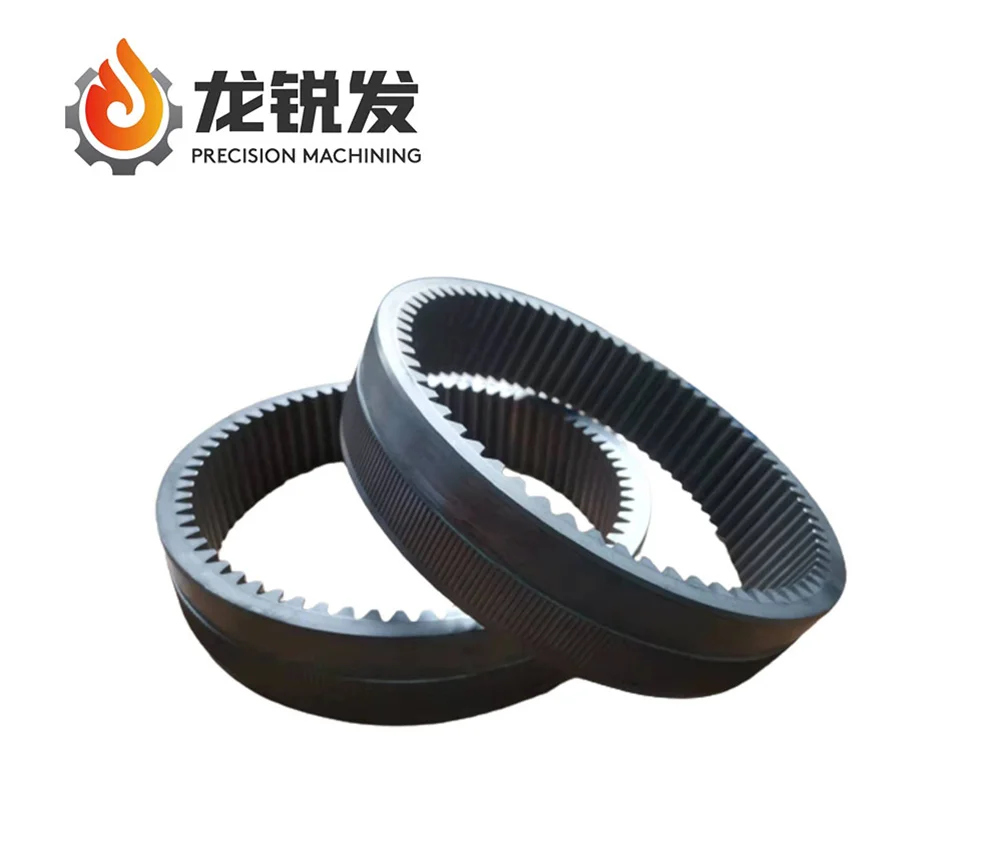

Precision ring gears are circular gears with teeth located on either the inner or outer circumference. When mounted with corresponding pinions or planetary gear systems, they provide torque multiplication, speed reduction, and angular displacement control. These gears are typically produced from high-strength alloy steels and heat-treated to enhance surface hardness and fatigue resistance. The precision of the tooth geometry—defined by parameters like pitch diameter, pressure angle, lead accuracy, and radial runout—greatly influences the overall mechanical system's performance.

In engineering machinery, especially where loads are heavy and operational cycles are continuous, the accuracy of gear meshing must be meticulously maintained. Precision class gears, such as AGMA Class 10 or DIN Class 6 or better, are often required.

2. Applications in Slewing Drives and Rotary Platforms

One of the most prominent applications of precision ring gears is in slewing drives, which are pivotal in rotating heavy equipment or platforms. In such systems, the ring gear—typically with internal teeth—is mated with a worm or pinion gear, allowing the entire load-bearing structure to rotate smoothly and with precision.

Examples:

* Excavators and Cranes: Ring gears allow the superstructure to rotate on a slewing ring bearing. High load-carrying capacity and shock resistance are essential.

* Wind Turbines: The yaw drive mechanism uses precision ring gears to align the nacelle with the wind direction, ensuring optimal energy capture.

* Aerial Work Platforms: Ring gears support the rotation of lifting booms, enabling safe and accurate maneuvering.

For these applications, the gears must exhibit high tooth strength, corrosion resistance (often achieved through surface coatings), and tight tolerances to minimize backlash and ensure position repeatability.

3. Integration in Planetary Gear Systems for Transmission

Precision ring gears form a core part of planetary gear systems, commonly used in the transmissions of heavy-duty engineering vehicles and construction machinery. These systems consist of a central sun gear, multiple planet gears, and an internal ring gear forming the outer boundary.

Advantages:

* High Torque Density: Planetary systems can transmit significant torque in a compact footprint.

* Load Sharing: Multiple planet gears distribute the load, reducing wear and improving gear life.

* Efficiency: These gear sets exhibit excellent mechanical efficiency, often above 95%.

Engineering Machinery Usage:

* Hydraulic Excavators: Used in the swing drive and travel motors.

* Road Rollers and Pavers: Enable smooth operation of drum drives and propulsion systems.

* Wheel Loaders and Skid Steers: Provide effective torque multiplication in drive trains.

Precision manufacturing of the ring gear is critical here to ensure uniform load distribution among the planet gears, which otherwise could lead to premature failure due to misalignment or uneven stress.

4. Precision Gearing in Robotics and Automation within Engineering Systems

With increasing integration of automation in engineering machinery, such as automated welding arms, CNC systems for fabrication, and robotic assembly equipment, the use of precision ring gears in harmonic drives and cycloidal reducers has grown significantly. These systems demand high accuracy, zero backlash, and compact design.

Use Cases:

* Robotic Arms in Construction: For precision placement of materials, welding, or manipulation in prefabrication plants.

* Automated Machining Centers: Rotary tables or indexing heads use ring gears to provide repeatable rotational motion.

* Tunnel Boring Machines (TBM): Rotary cutting heads use ring gears for synchronized motion control under extreme loading.

In these scenarios, ring gears must exhibit ultra-high positional accuracy (arc-min level) and low inertia to allow for high acceleration and deceleration rates. Advanced lubrication systems and surface coatings (like PVD or nitriding) are often used to extend operational life.

5. Use in Gear-Driven Axles and Final Drives

Heavy-duty vehicles such as bulldozers, graders, and dump trucks utilize precision ring gears in their axle differentials and final drive assemblies. The ring gear works with a pinion to convert rotational motion from the driveshaft to the wheel axles, allowing torque delivery and directional control.

Design Challenges and Requirements:

* Shock Load Resistance: Off-road conditions subject gears to unpredictable forces.

* Wear Resistance: Continuous operation demands high resistance to abrasive conditions.

* Noise and Vibration Control: Precision grinding and tooth profile modifications (like crowning or tip relief) are used to mitigate NVH (Noise, Vibration, and Harshness).

Materials like carburized steel (e.g., 8620 or 9310) are chosen for their case hardness and core toughness. Final gear sets are often tested using noise signature analysis to validate gear quality.

6. Precision Ring Gears in Hydraulic Motor Assemblies

In certain hydraulic machinery, gerotor-type hydraulic motors incorporate ring gears with lobed internal profiles to enable compact, high-torque rotary motion. These motors are extensively used in skid steers, drilling rigs, and augers. The ring gear's lobes must be machined to precise profiles with high smoothness to ensure efficient hydraulic sealing and torque output.

Features:

* Low-speed, high-torque output

* Smooth motion ideal for precise positioning

* Compatibility with compact motor designs

7. Material Selection and Surface Treatment Technologies

To meet the demanding environments of engineering machinery, ring gears must be made from carefully selected materials and undergo specialized treatments:

* Materials: SAE 4140, 4340, and 8620 steels; forged or cast as needed.

* Heat Treatment: Carburizing, nitriding, induction hardening to enhance surface hardness and wear life.

* Surface Finishes: Shot peening for fatigue resistance; phosphate or zinc coatings for corrosion resistance.

* Precision Grinding: For ultra-fine finish and tight tolerance maintenance.

Manufacturing standards often conform to ISO 1328, AGMA 2015, or DIN 3962, depending on application and regional industry practices.

Conclusion

The application of precision ring gears in engineering machinery is vast, spanning motion control, power transmission, and structural rotation systems. Their versatility, when combined with high mechanical efficiency and compact integration capabilities, makes them indispensable across construction, mining, agricultural, and automated machinery. As engineering machinery evolves with smarter controls, energy-efficient drive systems, and increasing emphasis on durability and precision, the role of advanced ring gear technology will only grow in relevance.

Manufacturers and system designers must continue to innovate in gear design, materials science, and manufacturing techniques to meet the emerging demands of modern engineering machinery. Whether in a slewing ring of a high-tonnage crane or the final drive of a tunneling machine, precision ring gears remain a cornerstone of mechanical motion and torque control in the industrial world.

www.lrfgears.com

Longruifa