In the realm of modern food production, industrial baking processes demand consistent quality, high throughput, energy efficiency, and automation. The industrial heat radiation tunnel oven has emerged as a cornerstone technology in meeting these stringent requirements, especially in large-scale baking operations. This sophisticated baking apparatus employs radiant heat transfer to deliver uniform thermal energy across products as they travel continuously through the oven chamber. In this blog post, as a high performance industrial tunnel oven exporter, Baimai will share the application of industrial heat radiation tunnel oven in baking.

Principles of Heat Radiation in Tunnel Oven

Radiation is one of the three primary modes of heat transfer, alongside conduction and convection. In a radiant heat tunnel oven, thermal energy is transmitted directly from heated surfaces (typically infrared emitters or high-temperature elements) to the product without relying on a conductive or convective medium. This direct form of heat transfer results in more precise control over baking profiles and rapid surface heating.

Radiant heat sources used in tunnel ovens may include:

* Electric infrared (IR) heaters, which emit radiation in the near or mid-infrared spectrum, efficiently heating product surfaces.

* Gas-fired radiant tubes, which emit radiant heat through the combustion of natural gas or LPG.

* Ceramic radiant panels, often used to ensure uniformity of heat distribution.

These sources are strategically arranged along the length and width of the tunnel to provide consistent thermal exposure to all parts of the baked product.

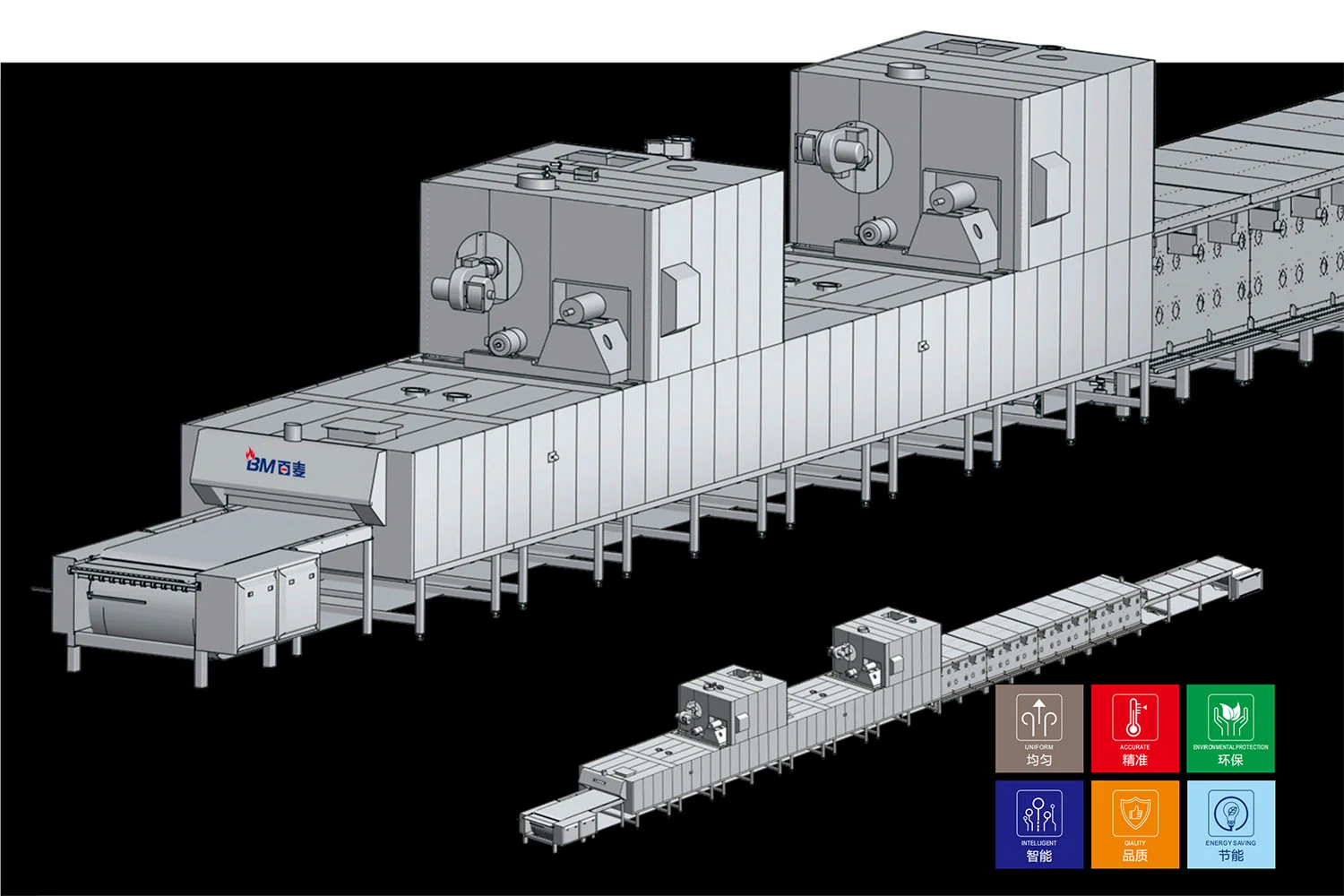

Structural Composition of Heat Radiation Tunnel Oven

The typical industrial heat radiation tunnel oven is a long, enclosed chamber divided into multiple heating zones. Each zone is independently controlled to allow specific thermal profiles to suit various stages of the baking process. Core components include:

* Conveyor System: A continuous belt, often made of stainless steel mesh or heat-resistant materials like Teflon or fiberglass, transports the product through the oven.

* Heating Chambers: Each chamber is equipped with radiant heaters positioned above and/or below the conveyor to ensure even baking.

* Insulation and Enclosure: High-efficiency thermal insulation minimizes energy losses, and the chamber design prevents heat leakage, ensuring consistent thermal conditions.

* Ventilation and Exhaust System: Controls moisture and volatile organic compounds (VOCs) produced during baking.

* Control Panel: Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) allow real-time monitoring and precise control over temperature, conveyor speed, and zone configurations.

Application of Heat Radiation Tunnel Oven in Baking Processes

The industrial heat radiation tunnel oven is widely applied in the production of various baked goods, including bread, biscuits, cakes, crackers, pizza bases, and pastries. Its utility is defined by how it addresses key challenges in commercial baking.

1. Surface Browning and Crust Formation

Radiant heat effectively targets the surface of the product, promoting Maillard reactions and caramelization. This results in appealing browning, enhanced flavors, and desirable textures without over-drying the interior.

In products like artisan bread and pizza crusts, radiant heat contributes significantly to the development of blistered, charred surfaces associated with traditional wood-fired ovens.

2. Energy Efficiency and Rapid Heat Transfer

Because radiation does not rely on heating air or other intermediaries, heat transfer is nearly instantaneous and efficient. This allows quicker startup times and reduced energy consumption per batch.

Radiant tunnel ovens maintain high thermal efficiency with faster throughput, particularly advantageous in continuous production lines.

3. Precise Thermal Control

The ability to fine-tune each heating zone enables tailored baking curves for different products. For example, initial zones may apply intense heat for oven spring in bread, while final zones maintain lower temperatures for controlled drying and moisture reduction.

This zoning also enables flexible operation across a broad product portfolio without mechanical modification.

4. Consistency and Scalability

The continuous conveyor-driven system ensures uniform exposure to radiant heat across all product units, eliminating variability often encountered in batch ovens.

High scalability supports large-scale production with minimal human intervention, ideal for meeting industrial demands.

Integration with Automation and Quality Control

Modern industrial tunnel ovens are integrated into fully automated baking lines, which include dough forming, proofing, baking, cooling, and packaging units. This integration supports:

* Real-time Quality Monitoring: Infrared sensors and thermal imaging cameras monitor product temperature profiles and surface coloration.

* Smart Oven Feedback Loops: Adaptive control algorithms adjust heat intensity or conveyor speed based on product feedback to maintain quality.

* Digital Twin and Predictive Maintenance: Advanced ovens are integrated with IIoT (Industrial Internet of Things) platforms for predictive diagnostics and optimization.

Comparative Advantage Over Convection Tunnel Oven

While convection ovens circulate hot air around the product, radiation tunnel ovens provide:

* Faster response times and surface heating

* Lower energy costs for products requiring intense top heat

* Less moisture loss, preserving product softness in items like cakes or enriched bread

* Superior browning in short timeframes, especially for thin or flat products

That said, for products requiring deep internal baking (like thick loaves), radiation ovens may be used in hybrid configurations with conduction or convection assistance.

Technical Considerations and Challenges

Despite their advantages, radiant heat tunnel ovens come with technical constraints:

1. Limited Penetration Depth

Radiant energy primarily affects the product surface. Additional heat transfer methods may be necessary for volumetric baking of thick items.

2. Material Sensitivity

Not all products tolerate the intense surface heating of radiation; delicate batters or products with uneven surfaces may suffer from scorching or irregular coloring.

3. Maintenance Requirements

Infrared emitters and radiant panels require regular cleaning to maintain emissivity and efficiency. Dust or baked-on residue can impede radiation and create hot spots.

4. Heat Uniformity

Achieving uniform radiation across wide conveyors demands careful heater placement and calibration. Temperature mapping and periodic adjustments are essential.

Environmental and Energy Sustainability

With rising energy costs and stricter environmental regulations, tunnel ovens are evolving to incorporate:

* Energy Recovery Systems: Capturing exhaust heat to preheat incoming air or water for other plant processes.

* Smart Load Management: Adjusting heat output based on production volume to avoid overconsumption.

* Green Fuel Alternatives: Transitioning from natural gas to hydrogen or electricity from renewable sources for radiant heat generation.

These advancements align industrial baking operations with sustainability goals and carbon footprint reduction initiatives.

Conclusion

The industrial heat radiation tunnel oven plays a critical role in modern baking operations, offering precision, efficiency, and scalability. Its unique advantages in surface browning, energy savings, and consistency make it an indispensable component in high-throughput production environments. By understanding its working principles, integration challenges, and evolving technology, food manufacturers can fully harness its potential to deliver high-quality baked goods at industrial scale.

www.bmbaking.com

Baimai